Hot Testing of Safety/Relief valves while operations continue. Cold Testing of valves on-site and in the workshop. Legatest will increase efficiency and save your organization money from day one.

In the past, valve testing revolved around, workshops and mostly importantly shutting down the line. The whole process was both time consuming and costly – but there is an alternative.With Legatest you can carry out accurate assessments of safety and relief valves in situ and under pressure – Hot Testing. There’s also the option of Cold Testing to assess the Performance of new and existing valves.

Developed and patented world-wide by Furmanite, Trevistest is fast, safe and efficient. Operated in accordance with strict control procedures centred on ISO 4126-1, Legatest can be used with most safety and relief valves manufactured for use in steam, air, gas process and water systems. These include conventional spring valves, torsion bar valves and pilot operated valves.

How does Legatest work?

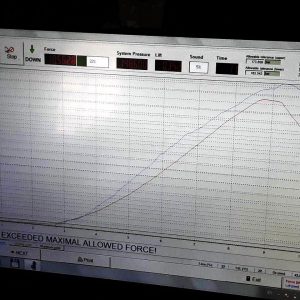

Here’s the basic principle. A force is applied to the valve spindle to overcome the spring tension of the valve. This is achieved using an Electric power jack linked to an electronic transducer. A computer is then used to measure the force applied. By combining this data with information on the valve seat and line pressure of the valve it is possible to assess the set pressure. Serving every sector Fossil, hydro and nuclear power generation offshore oil and gas production

Refineries and petrochemical plants Fertilizer plants Food Processing plants Pulp and paper plants and …